FEATURE

1. The barrel, screw and die is made of high-quality steel 38GrMoAIA, precisely formed by heat treatment, and it has the features of high yield, good plasticization effect, and long operating life.

2. The cylinder is sub-chain heated, and the temperature is controlled electronically and automatically, constant temperature.

3. The use of VVVF drive motor enabled the drive smooth and control flexible. The adoption of four times traction made it possible to suit a wide range of the width of the blown film and improve yields.

4. Using new screw diameter ratio 23:1, which is more suitable for high melt viscosity, thermal stability, raw materials plastination.

5. Using water tank heating system, by heating and through the water tank, the film is very clean and transparent.

6. The design of the machine is reasonable, less power consumption, and high output.

Also it can be used widely in various areas and the quality is reliable. Besides, the operation and maintenance is easy. So it is an economic choice for you.

PARAMETER

|

Type |

Horizontal |

Vertical |

||||

|

Model |

PVC45*28-400 |

PVC60*23/600 |

PVC65*23/800 |

PVC70*23/1000 |

||

|

Film width |

30-400mm |

300-600mm |

500-800mm |

700-1000mm |

||

|

Film thickness |

0.01-0.08mm |

0.02-0.08mm |

0.02-0.09mm |

0.25-0.10mm |

||

|

Capacity |

30kg |

40kg |

50kg |

60kg |

||

|

TD shrinkage |

52% |

50-52% |

50-52% |

50% |

||

|

MD shrinkage |

2% |

6% |

6% |

8% |

||

|

Screw diameter |

45mm |

60mm |

65mm |

70mm |

||

|

Screw ratio |

28:1 |

23:1 |

23:1 |

23:1 |

||

|

Main motor power |

11kw |

15kw |

18.5kw |

22kw |

||

|

Main heating power |

10kw |

10kw |

13kw |

16kw |

||

|

Rewinding motor |

3kw |

3kw |

4kw |

5.5kw |

||

|

Temperature control |

6 sets |

6 sets |

7 sets |

8 sets |

||

|

Traction speed |

5-40m/min |

5-40m/min |

5-40m/min |

5-40m/min |

||

|

Rewinding roll |

500mm |

700mm |

900mm |

1100mm |

||

|

Weight |

2.2T |

2.5T |

3.0T |

3.5T |

||

|

Power supply |

380V, 3P, 50Hz |

|||||

|

Dimension |

9.0*1.6*1.5 |

5.5*2*3.2 |

6*2.2*3.6 |

6.5*2.5*4 |

||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

All of our machines with 1 year guarantee.

Our machines are well favoured by customers due to easy operation, perfect performance, easy maintenance good & prompt after sale service.

If you need installment or training service,we can send engineer to your country,

help you install machines,training your workers to use machine(you need pay double way air tickets,salary,food,hotel for our engineer).

Install machines in Saudi Arabia.

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

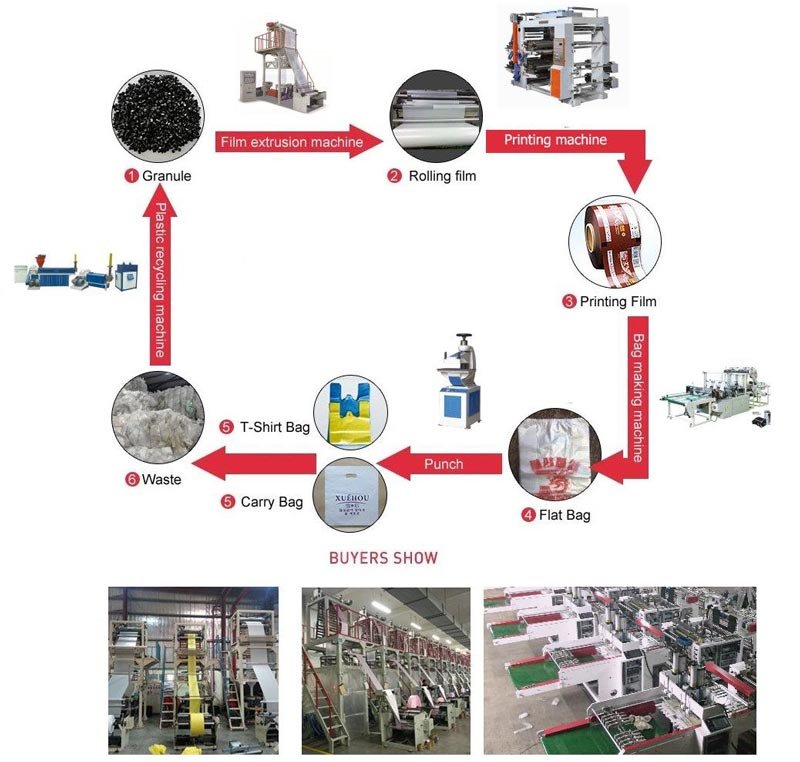

How To Find Polyethylene For Blown Film Extrusion?

Extrusion Film Extrusion use Polyethylene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company