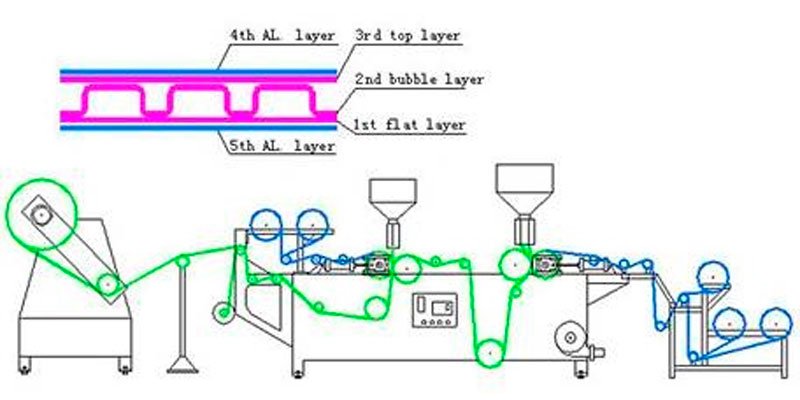

A multi-layer air bubble film machine is a type of machinery used to produce air bubble film with multiple layers. This type of film is commonly used for packaging and cushioning purposes, providing a protective layer to items during transit and storage.

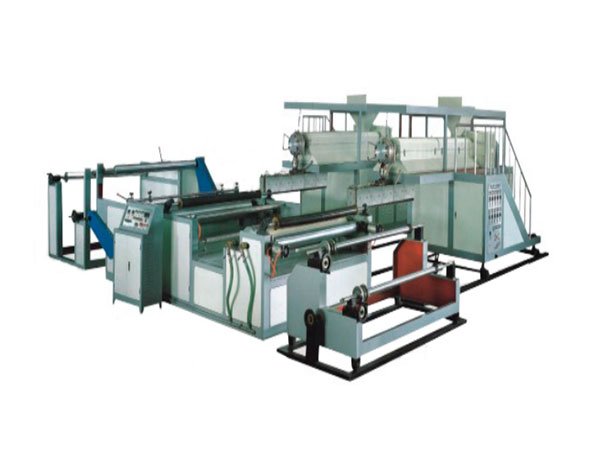

The machine typically consists of a series of rollers, extruders, and heating elements to create the layers of the film. The process involves feeding the raw materials into the machine, which are then melted and formed into the desired thickness and shape. The air bubbles are created by the machine as the film is being produced, providing the cushioning effect.

Air Bubble Film Extrusion Line

Air Bubble Film Machine Main Technical Variables:

| Model | KDPEG-1000 | KDFPG-1200 | KDPEG-1500 |

| Raw Material | LDPE,recycle material,Masterbatch and additives material | ||

| Screw Diameter | φ65mm+φ50mm | φ75mm+φ60mm | φ90mm+φ70mm |

| Bubble film Max. width | 600mm | 1200mm | 1500mm |

| Bubble Film Layer | 4 layers | ||

| Bubble Film Color | Transparent,Black,Red,White,blue…bag color changed by Masterbatch | ||

| Laminate film | PE film,PET film,aluminum film,non woven film,Paper | ||

| Output | 55kg/h | 70kg/h | 90kg/h |

| Total power | 75kw | 82kw | 98kw |

| L/D Ratio Of Screw | 28:1 | 28:1 | 28:1 |

| Water Consumption | 0.5m3/h | 0.5m3/h | 0.5m3/h |

| Machine Weight | 3.5 | 4.5 | 5 |

| Power Voltage | 220V,380V,440V(Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz…) | ||

| Air Shaft Diameter | without paper core ,58mm,76mm | ||

| Machine Working Time | 24 hours*7 | ||

| Warranty | 1 year | ||

| Technical Assistance | Engineers available to service machinery overseas | ||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

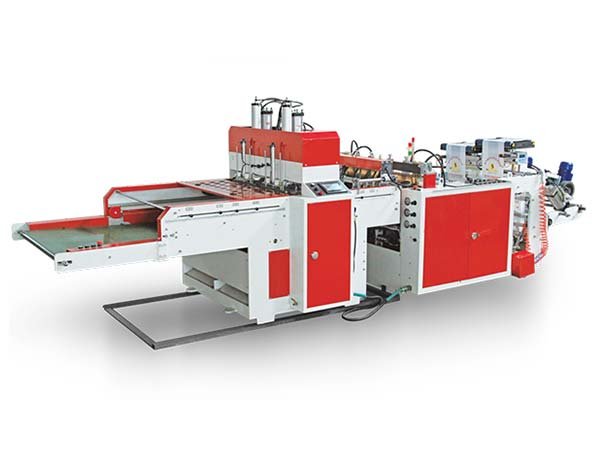

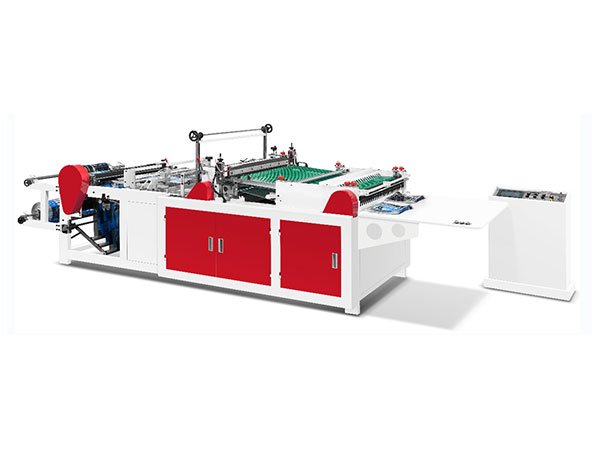

Bubble Film Machine Picture

Our Main parts cooperator as following brand,but standard parts all made from China.

Multi-layer air bubble film machines can produce films with different combinations of materials, such as LDPE, LLDPE, and HDPE, to achieve specific properties and performance characteristics. Additionally, these machines may also have features for customizing the width, length, and pattern of the air bubble film to meet different packaging requirements.

Overall, a multi-layer air bubble film machine is a versatile and efficient solution for producing high-quality protective packaging materials for various industries.