Properties and uses:

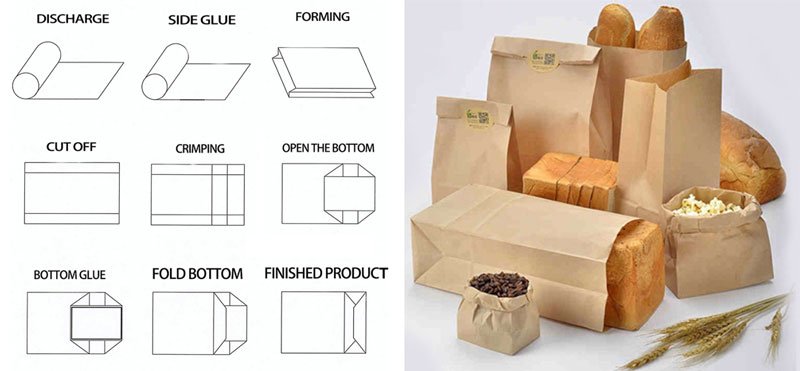

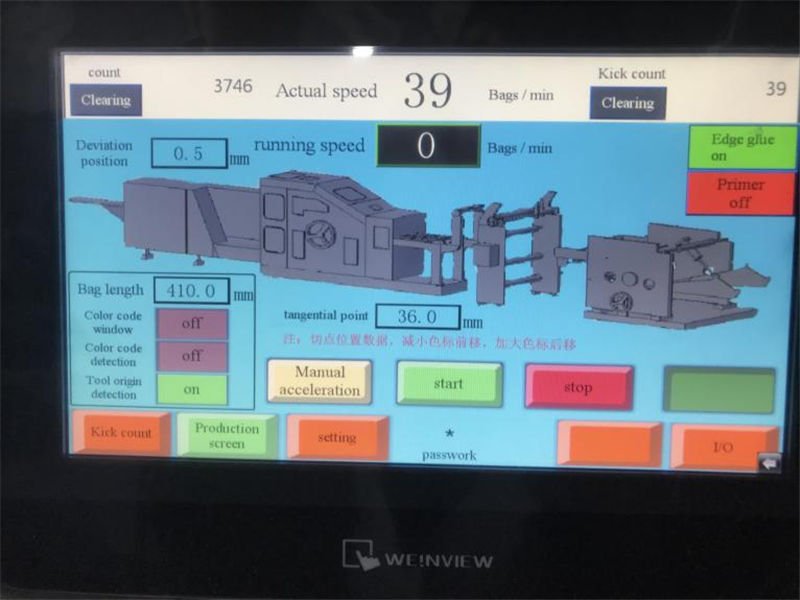

This machine is composed of roll unwinding (hydraulic feeding, automatic web guide, constant tension), side gluing, printing electric eye tracking, base paper into cylinder, fixed-length traction cutting, bag bottom indentation opening, bag bottom gluing, bag bottom molding, bag sending etc.The whole machine is controlled centrally by PLC touch screen and servo motor controls the length of paper bag.

It can pretend 2 color /4 color printing group, bag surface window lamination device and handgrip hole device according to your need.Can be matched with rope twisting, flat rope handlebar machine, rewinding machine, etc., to make the products more competitive and diversified.

Technical Parameter:

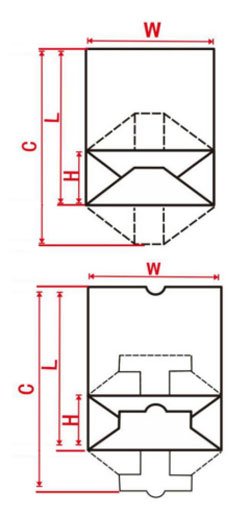

| Model | KDFD-330 |  |

| Paper Roll Length | 270-530mm(C) | |

| Paper bag length | 225-450mm (L) | |

| Paper bag width | 150-330mm (W) | |

| Paper bag bottom width | 60-160mm (H) | |

| M Side Insert Depth | 30-90mm | |

| Paper thickness | 60-160g/m2 | |

| Machine Speed | 30-160pcs/min | |

| Paper roll width | 380-950mm | |

| Roll paper diameter | 1200mm | |

| Diameter of paper core | 76mm(3”) | |

| Machine power | 3phase,380v ,12kw | |

| Machine weight | 8000kg | |

| Machine size | 10500x3700x1900mm | |

| FOB Ningbo seaport price | USD78000 |

1.Use Taiwan Wenview Touch Screen Human-Computer Interface, operate and control easily.

2.Adopt Japan Mitsubishi PC Control, integrated with optical fiber,ensure high speed running steadily.

3.Japan Mitsubishi Servo Motor and Germany Original SICK Photoelectric Eye Correction, tracking printing bag accurately.

4.Raw material loading and unloading adopts motor lifting structure , and unwinding adopts automatic constant tension control.

5.Raw material loading and unloading adopts motor lifting structure , and unwinding adopts automatic constant tension control.

Note: The purchased parts used in this machine will be replaced by a brand of the same quality not less than the existing brand when the equipment is upgraded or updated. The Seller reserves the right without further notice.