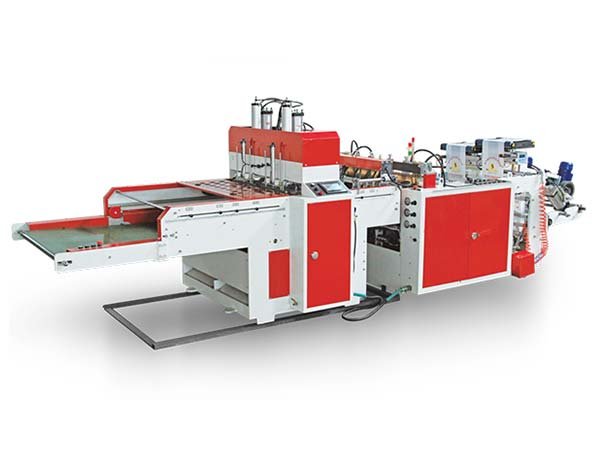

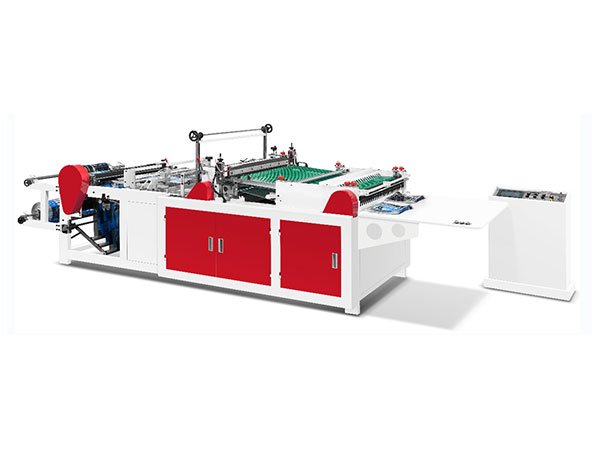

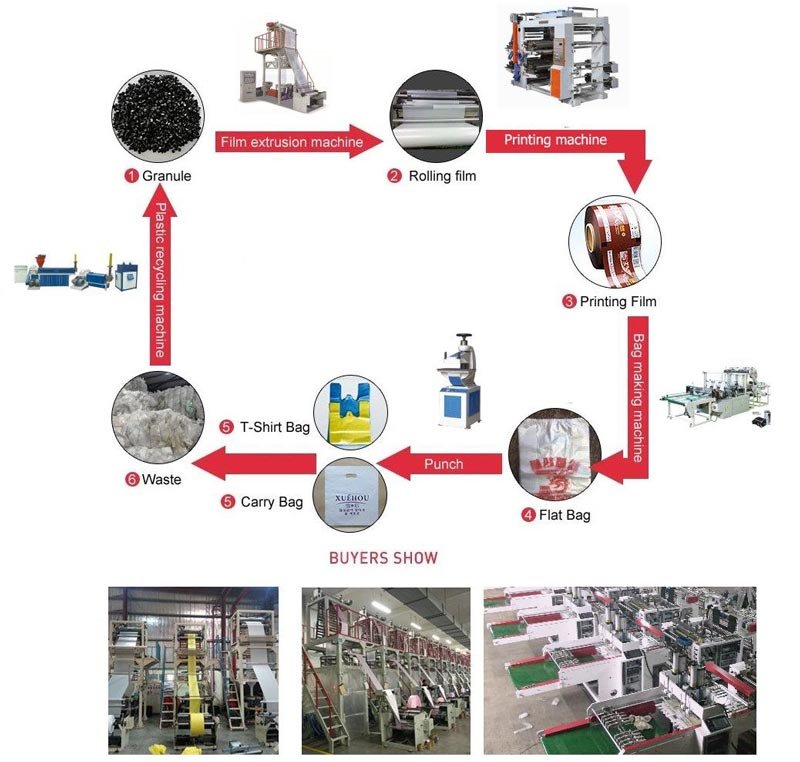

Cling film machine with following equipment: one screw, one motor motor,two inverter,simple design,easy operation,low noise, stable running, especially winding part is controlled by PLC touch screen. The machine is equipped with extruder, traction part, leveling part, edge trimming, winding and finished roll automatic changing etc.

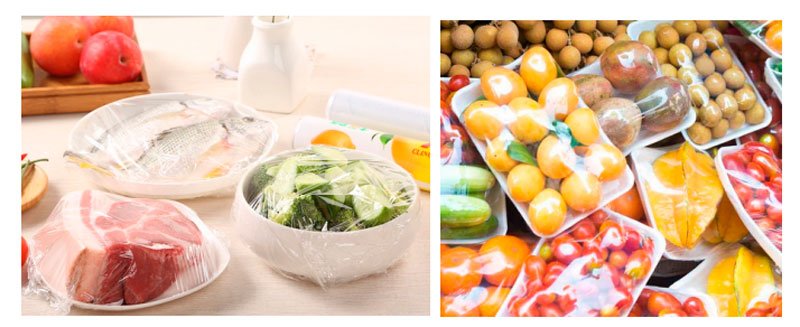

Cling film is a kind of plastic film. As a kitchen product, plastic wrap can block moisture and prevent direct contact between air and food. It is mainly used for cooking, holding food, preserving food, or making some materials that can be easily cleaned.

Optional Equipment:

1)Auto load

2)Auto dry hopper

3)Motorize net changer

4)Hydraulic net changer

5)glue pump

6)air compressor

7)Chiller

8)Waste film crush online

Main Technical Parameter

| Model | KD-600×1 |

| Material | LLDPE |

| Screw Diameter | φ55mm |

| Film Layer | One layer |

| L/D Ratio Of Screw | 30:1 |

| Speed of Screw | 10-120rpm |

| Width of die head (mm) | 750mm |

| Film Width | 600mm (300*2roller) |

| Film Thickness | 0.007–0.012mm |

| Film Color | transparent |

| Main Motor Power | 15kw |

| Max Output | 30kg |

| Heating power | 20KW |

| Water Consumption | 0.5m3/h |

| Air Consumption | 3m3/h |

| Machine Weight | 4T |

| Overall Dimensions(L*W*H) | 60*15*25cm |

| Total Power | 45kw |

| Power Voltage | 220V,380V,440V |

| Machine Working time | 24 hours*7 |

| Material Core Diameter | 76mm(3 inch) |

| Warranty | 1 year |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Our Main parts cooperator as following brand,but standard parts all made from China.