| three layers LDPE HDPE EVA Film Blowing Machine |

| three layers LDPE LLDPE EVA film extursion |

| three layers LDPE PP EVA Film Blowing Machine |

| three layers LDPE MLDPE EVA Film Blowing Machine |

| three layers MLDPE HDPE EVA Film Blowing Machine |

| three layers water bag Film Blowing Machine for |

| three layers blown film extrusion |

Three layers film blowing machine,use polyethylene High-density polyethylene HDPE, Low density polyethylene (LDPE),EVA to produce function film,suit for general packaging products such as hot shrink film,pack film,water bag and other products.

Main machine: All main machines of adopt screws that feature excellent hardness and wear resistance. It can still plasticize a large number of particles under the environment of high speed and high pressure.

Die-head: 3-layer co-extrusion blown film machines adopts a special structure with 3-layer cone.We are sure that after a high degree of polishing and coating, each runner has the ability to clean itself under the high pressure and high speed scouring of high-speed screw

Optional Device:

1)Auto Loader

2)Air Compressor

3)Rotary Die Head

4)Double Side Winder(Back to back winder)

5)Up and Down

6)Embossing Cylinder

7)Air Shaft

8)Masterbatch Dosing device

9)Automatic Winder Changer

10) Corona treatment

Main Technical Variables

| Model | 3SJ-G1000 | 3SJ-G1200 | 3SJ-G1500 |

| Tube Film Width | 1000mm | 1200mm | 1500mm |

| Film Open Width | 2000mm | 2400mm | 3000mm |

| Material | LDPE,LLDPE,HDPE,MLDPE,EVA,recycle material | ||

| Air Ring | Double Lip Air ring | ||

| Screw Diameter | ф55×2 ф60×1 | ф60×2 ф65×1 | ф65×2 ф70×1 |

| Screw Ratio L/D | 28:1 | 28:1 | 28:1 |

| Screw Speed | 15-150r/min | 15-150r/min | 15-150r/min |

| Main Motor Power | 15Kw×2 18.5Kw×1 | 18.5Kw×2 22Kw×1 | 22Kw×2 30Kw×1 |

| Capacity(Single) | 50kg/h | 80kg/h | 100kg/h |

| One side film thickness | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Power | 76Kw | 88Kw | 102Kw |

| Machine size(cm) | 66×41×50cm | 68×43×60cm | 70×48×75cm |

| Machine Weight | 4T | 5T | 6T |

| Power Voltage | 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz…) | ||

| Material Core Diamater | 76mm | ||

| Machine Working Time | 24 hours * 7 days | ||

| Warranty | 1 year | ||

| Technical Assistance | Engineers available to service machinery overseas | ||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

All of our machines with 1 year guarantee.

Our machines are well favoured by customers due to easy operation, perfect performance, easy maintenance good & prompt after sale service.

If you need installment or training service,we can send engineer to your country,

help you install machines,training your workers to use machine(you need pay double way air tickets,salary,food,hotel for our engineer).

Install machines in Saudi Arabia.

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

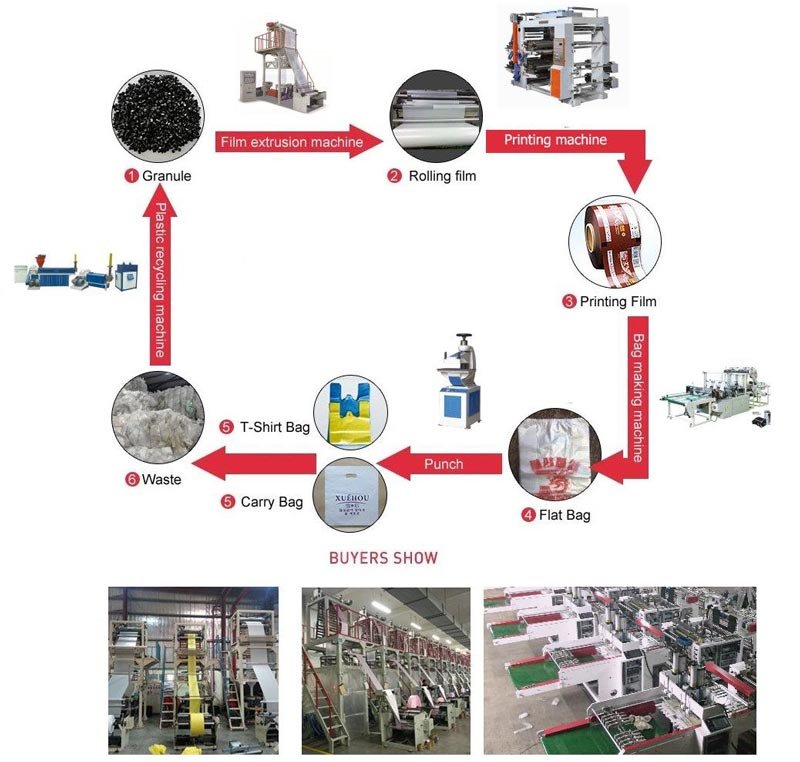

How To Find Polyethylene For Blown Film Extrusion?

Extrusion Film Extrusion use Polyethylene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company